Produce and pay the quantities you really need,

this is our vision of the co-filling and contract packaging.

You are not ready to run production and package your products on a large scale? You don’t have to! Our solutions are also tailored for low volume productions.

✓ Transparent pricing structure

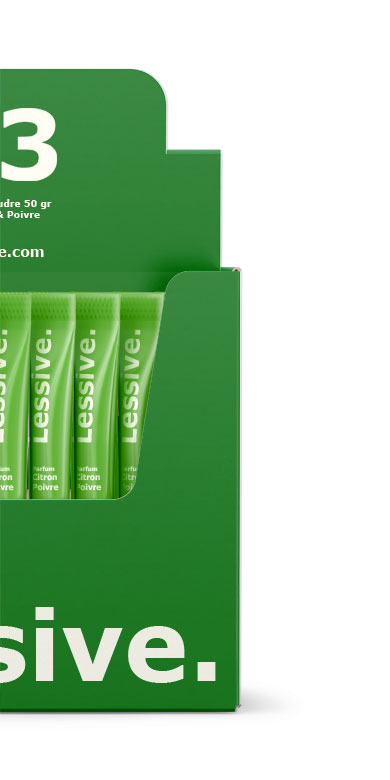

Select an efficient packaging format for your products. Choose a packaging which meets the best your constraints and your expectations.

✓ No set up fees, trial costs or minimum orders

✓ Experienced team in unusual requests

Savoir-faire

Flexible single-dose from 3 ml to 5 L:

✓ Granular or pasty liquids with high viscosity:

purees, jams, dips, honey, sauces

hydroalcoholic gels, liquid soaps, oils…

✓ Dry, powder or granules:

yeasts, food supplements, spices

baking soda, matcha tea, pumpkin seeds, chia seeds…Our machines are designed for inerting and blanketing packaging- to ensure a shelve-stable packaging.

Whether your products require ambient, chilled or frozen space, Dozett has the systems to ensure that they stay within spec. 100% of the time. Our temperature controlled facility incorporates a dedicated liquid and powder filling cleanroom.

We pack all types of raw materials, our offers can be customized and adapted to your needs.

It’s easy!

Custom

Packaging

Inbound &

Storage

Single-dose

Filling

Quality

Control

Labelling

Packing

Warehouse &

Pick-up

Eco-friendly together!

Dozett continually seeks new product offerings to enhance our ever widening basket of friendlier film products for our environment. We focus our efforts to identify and provide substrates that are made with a lower carbon footprint and/or a positive impact on the waste stream:

– Films made with 100% recycled products

Compostable/biodegradable packaging do not fully decompose in a landfill because the necessary oxygen and temperature to decompose a product is too low in the landfill.

– Plant based (sustainable) virgin resins

Test, modify, validate!

Do your customers want to touch, smell and taste your product before it goes to market? Do you need to perform bacteriological tests in the laboratory under real conditions?

Dozett makes sampling and pre-production possible for all projects:

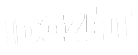

✓ Minimum packaging of 1500 single doses*

✓ Color printing of your complex

✓ With or without modified atmosphere*Example for a sample of berlingots with aluminum triplex complex- 60 ml.

Whether you are a small local producer, a new online store on a platform like Amazon, Etsy, eBay or Instagram, we mini-doz your product ideas into reality!

Dozett produces your samples under the same conditions and processes as our mass productions, offering the same guarantees and finishes as large-series to ensure your product integrity stays intact.

Pay what you produce, no fixed charge.

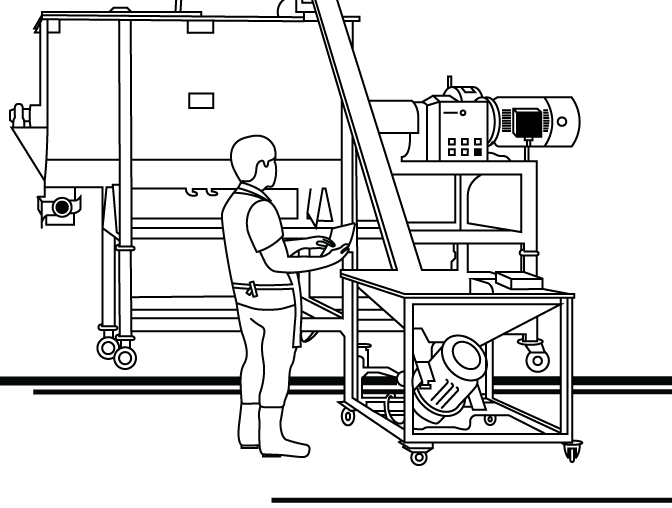

Ingredient blending

When you’ve sourced all the ingredients, created a formulation / recipe based on these ingredients and need it blended in commercial quantities, Dozett can assist you as your dry powder blending partner.

We offer both a holistic contract food manufacturing solution and the expertise to process your formulation to your specifications.

Benefits of Dozett blending:

✓ Reduce time to market

✓ Consistency and quality at all stages

✓ Quality reassurance to customers

Get a quote?

What’s your project?

If you have a question or simply need help to finalize your project, our team will assist you: [email protected]

Want to join us, become a Dozett partner or share an idea, tell us hello! We will respond as soon as possible.

Dozett has vast experience designing and developing new packaging tailored to your goals. By working directly with us, you’re assured of getting a dynamic, innovative product of your specifications. We also deliver specific services within the process if you need some extra support.

We are at your disposal to advise you every day and offer tailor-made solutions for your product, quality problems or any other issue. Whether it is a problem of profitability, complexity or reactivity, we adapt our organization to better manage your specific requests.